PEEK Machining – CNC Machining PEEK Plastic Services

PEEK is a special engineering plastic with excellent performance. Compared with other special engineering plastics, PEEK has many significant advantages. PEEK has high temperature resistance, excellent mechanical properties, good self-lubrication, chemical corrosion resistance, flame retardant, peel resistance, It has excellent properties such as radiation resistance, stable insulation, hydrolysis resistance and easy machining, which can be used to manufacture and process various mechanical parts, such as automobile gears, oil screens, shift starter discs, aircraft engine parts, automatic washing machine runners, medical Equipment parts, etc., are used in aerospace, automobile manufacturing, electrical and electronic, medical and food processing and other fields.

The technological development and breakthrough of PEEK not only meets the domestic production needs, but also the domestically produced PEEK materials and products are exported to foreign countries one after another, breaking the foreign technology monopoly. The technological innovation of PEEK material has changed the disadvantages of traditional peek machining methods such as low utilization rate, high cost, and difficulty in directly forming complex structures, and has realized the low-cost, high-precision, shape-controlling and rapid manufacturing of high-performance PEEK materials. PEEK combines a number of outstanding properties, so the PEEK application market is also constantly developed and innovated.

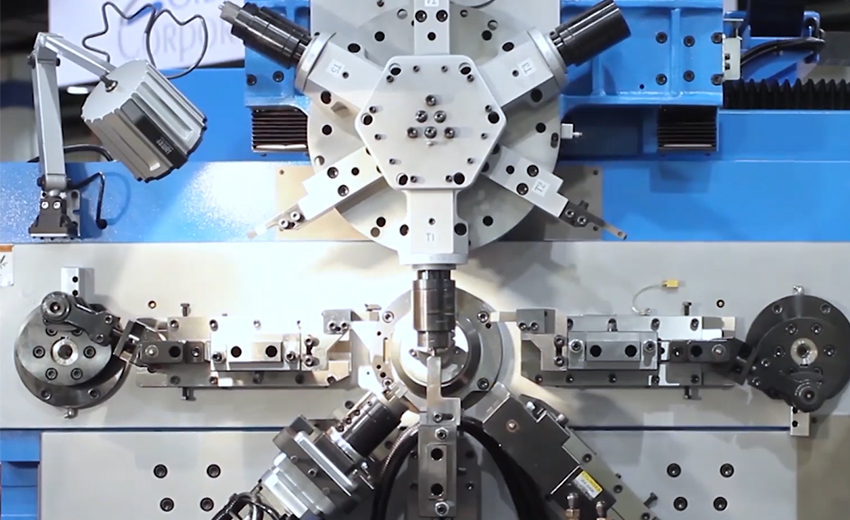

Pinjin is known for producing quality 5 axis machining,PEEK extrusion and swiss machining products from PEEK plastic material. We can machine intricate parts on our CNC Swiss machines and 5 axis machining centers.

The Innovation Of PEEK Performance Formulation

Polyetherketone blending can obtain a composite material with a specific melting point and a specific glass transition temperature, and the machining and molding properties of the material are improved; the composite material after blending PEEK and polyethersulfone has good mechanical properties, but also makes the resistance and combustion performance has been improved;the material made of special phenolic resin added to PEEK has special anti-friction performance;

The composite material made of PEEK and PTFE blended, while maintaining the high strength and high hardness of PEEK, It also has outstanding wear resistance and can be used to manufacture mechanical parts such as sliding bearings and sealing rings; PEEK can be modified and reinforced with various fibers such as carbon fiber and glass fiber to make high-performance composite materials. Fiber-reinforced PEEK composite The material has excellent creep resistance, damp heat resistance, aging resistance and impact resistance. Adding carbon fiber or glass fiber to PEEK can greatly improve the tensile and flexural strength of the material; adding whisker material to PEEK can improve the hardness, rigidity and dimensional stability of the material, and is used to manufacture large-scale petrochemical production lines. Ring and mesh valve plates for hydrogen compressors and LPG compressors, etc. The PEEK composite material reinforced and modified with inorganic nanomaterials is a new type of composite material that combines many characteristics of organic resins and high-performance inorganic nanoparticles. It can significantly improve the impact resistance and friction resistance of PEEK resins. Rigidity and dimensional stability further broaden the application range of PEEK resin.

The Innovation Of PEEK Forming Technology

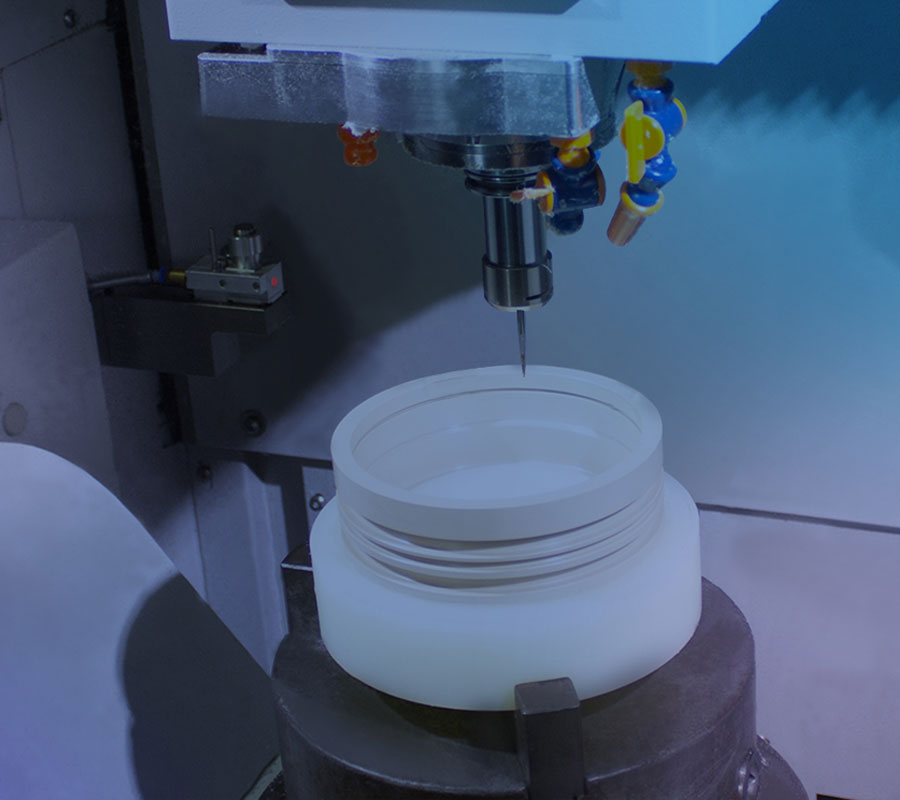

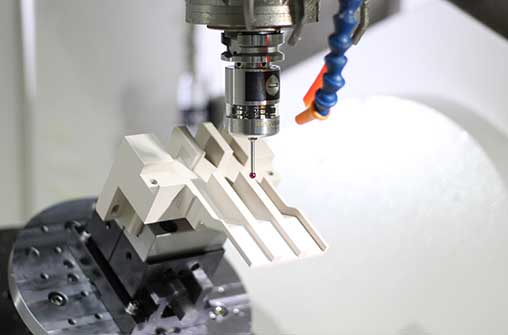

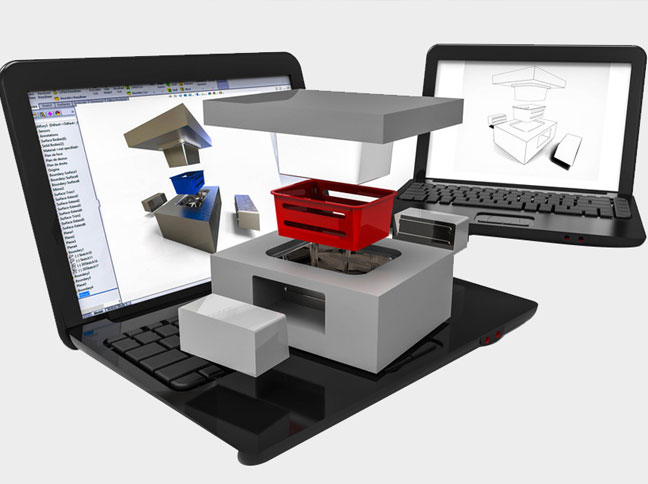

The forming methods of PEEK materials include extrusion, injection molding, blow molding, pressing, cnc machining(peek cnc milling,peek cnc turning,5 axis machining peek parts,swiss machining), etc.

At the same time as the development of processing technology, with the improvement of the market’s requirements for material properties, the modification and compounding of PEEK has become a hot spot in the development of the industry in recent years. In addition to chemical modification by changing the composition and/or ratio of the polymer main chain in the polymerization stage, common performance improvement methods in the industry include surface modification, blending modification, and composite filling enhancement, etc. Improve the forming processability and performance of PEEK.

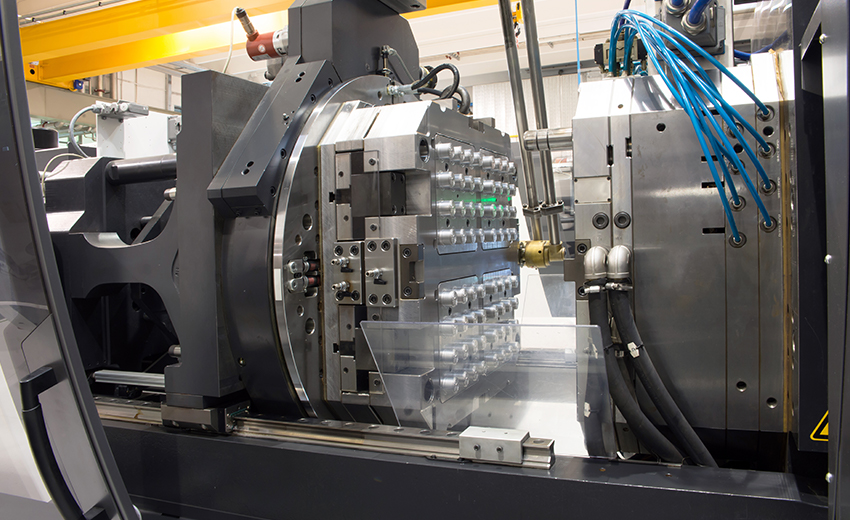

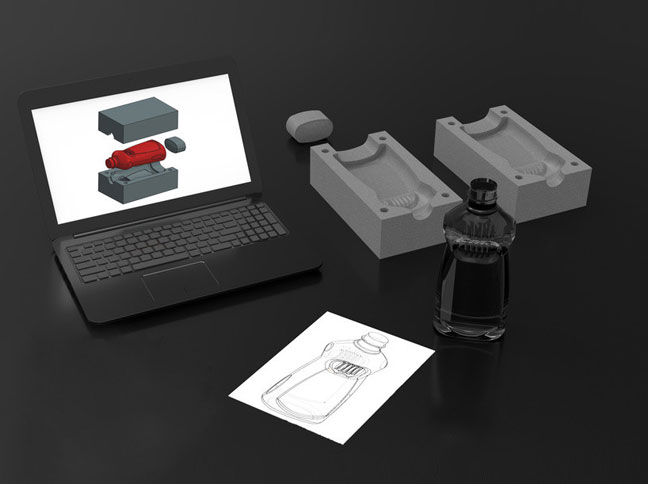

The advantage of PEEK injection molding is to process high-precision PEEK parts by open-mold injection, so as to help industrial customers develop high value-added products. Our company is an expert in the field of PEEK injection molding. From product samples to mold opening and injection molding, our company has a very complete set of solutions to meet the special needs of different customers. All kinds of difficult PEEK machined products can be produced to provide customers with Comprehensive technical support.

The Innovation Of PEEK Manufacturing Technology

PEEK manufacturing can be processed using conventional thermoplastic manufacturing equipment, and unfilled and filled grades are typically supplied as pellets, powders, or ultrafine powders.Pellets are usually recommended for manufacturing methods such as injection molding, extrusion, monofilament and wire wrapping.

Powders are suitable for compression molding, while ultrafine powders are commonly used in coatings, composite prepregs, and compression molding. Compared with metal materials and general engineering materials, PEEK is quite different from metal materials and general engineering materials in terms of thermal expansion, heat dissipation performance, elasticity, and wear resistance. Improper operation will cause adverse consequences. Therefore, PEEK materials should fully consider the characteristics of the material during manufacturing, and make adjustments in the use of tools and technical parameters, especially for products with larger specifications, heat treatment should be performed after processing to eliminate internal stress to avoid product cracking and deformation.

In order to meet customers’ requirements for the precision and complexity of PEEK manufacturing, Pinjin continuously improves its own technical capabilities and level, and carries out innovation and improvement of PEEK manufacturing technology. High-precision product machining, micro product manufacturing, free-form surface treatment, fine hole machining, roughness control processing, deburring control machining, welding and welding and fusion manufacturing can be performed.

China Top PEEK Machining Service Supplier

Pinjin inc has been focusing on the research and development and production of peek plastics since its establishment. The main technical personnel have ten years of experience in the application and development of special engineering plastics parts, so the products have passed the ISO9001 quality management system certification. In the future, Pinjin inc will continue to introduce foreign machining equipment and technologies, and is committed to promoting the application and development of special plastics in various industries and helping China’s special engineering manufacturing industry.

Pinjin focuses on PEEK special engineering plastic profiles extrusion molding and parts machining, and provides integrated solutions for R&D, design and production of special engineering plastic profiles and parts for different industries. The company has put into production a number of continuous extrusion production lines for profiles, PEEK bars, PEEK sheets, PEEK pipes, PEEK sheets, PEEK profiles, PPS rods, plates and tubes can be produced independently and in batches. After years of accumulation of experience, Pinjin has been able to produce PEEK profiles of various conventional specifications and have a large inventory, and can also customize and process unconventional PEEK profiles and PEEK profiles according to customer requirements. In addition, the company has horizontal injection molding machines, vertical injection molding machines, large-scale molding machines, high-precision CNC lathes, CNC machining centers, engraving machines, turning and milling and other mechanical machining equipment, specializing in customized machining of various specifications and different purposes. PEEK, PI, PPS, PEI and other parts.

According to the sample drawings and samples given by customers, the same peek plastic can be customized and machined to ensure accurate style and performance.

Through understanding and communication, according to the actual needs of customers, personalized special customization for customers to meet the different needs of customers.

With years of experience in PEEK application development, we can optimize the design and structure of PEEK parts according to different situations and save costs.

In-house mold/machining/injection molding/wire cutting workshop, with 200 pairs of molds, rich experience in mold making, support for mold opening, saving time for external mold development.

Pinjin inc is a new technological innovation enterprise with many years of production and cnc machining experience in PEEK products. application. Pinjin is committed to the production and development of PEEK profiles and other special engineering plastic profiles. Through its own continuous technological innovation, it has formed its own technology and intellectual property rights, maintained its leading position in industry technology, obtained market competitive advantages, and continuously carried out management and technical improvements. A team of highly efficient and skilled employees is the driving force behind the sustainable development of the company. Mutually beneficial cooperation with customers, cooperative development with stakeholders, improve the efficiency of enterprise operation, and become a leader in the industry and a technologically innovative enterprise.

PEEK CNC Machining And Injection Molding Parts Case Studies

Provide drawings (format: CAD, PDF, JPG, step, etc.) or samples. Information includes: quantity, material, precision tolerance, surface treatment and special requirements.Our company can modify or design the drawings appropriately according to customer needs.You can directly send the drawings to info@pintejin.com and notify by phone or information.

PEEK Injection Molding Services – PEEK Plastic Injection Parts Manufacturer

With decades of experience in plastic injection molding, Pinjin works with a wide variety of plastic materials and PEEK grades. As a China-leading plastics and composite machining company, we can employ HAITIAN injection machine to ensure efficiency and accuracy, even the most complex geometries and tight tolerances are required. CNC machined PEEK parts are fabricated based on customer requirements or CAD drawings submitted, our engineers and designers will help you improve the models to gain the best outcomes and reduce costs. If you want to develop your project about PEEK (Polyether ether ketone) products or prototypes, we are glad to discuss all the details with you. Consistent communication will also be kept during the production cycle of PEEK injection molding parts and machined parts.

“Goal is to make your ideas come to life one layer at a time.”

Contact Our Team

Our sales and engineering services are available at your convenience, whenever you need us. Whether it’s 11:00 pm on a Saturday night, or 7:00 am on Monday morning, it makes no difference to us. We’re always available to assist you with your order, or answer any questions you may have about our peek machining and peek injection molding services.

LOOKING FOR RECOMMENDATIONS

CHECK LATEST PEEK MACHINING REVIEWS

We share information, tips and things we’ve learned from our years in the PEEK machining and injection molding industry.