The widespread use of polymers has transformed our lives over the past 75 years or so. From commodity plastics to high performance polymers (HPP). Like PEEK, both can function in very demanding applications. PEEK not only plays an important role in the plastic part of the antenna port of the iPhone, but also has been widely used in the new HNB smoking set, and is the core raw material for heating peripheral components. Many of China’s top heat-not-burn products are using PEEK’s material solutions.

What Is PEEK Material?

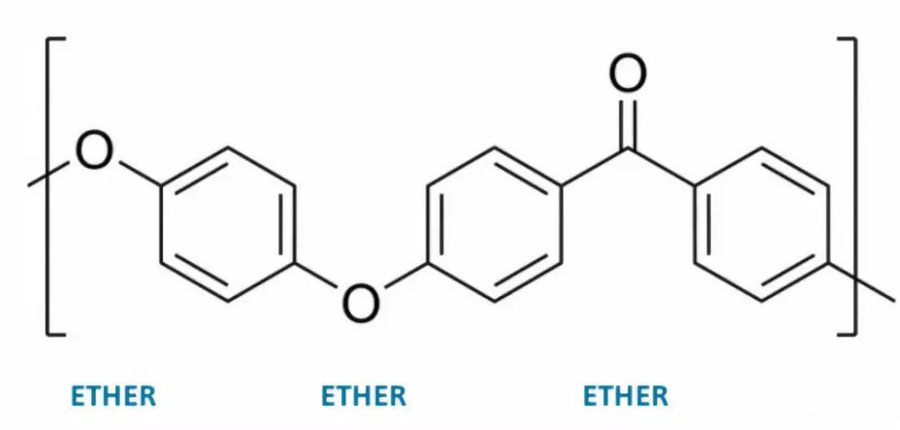

Polyetheretherketone (English name polyetheretherketone, PEEK for short) refers to a linear aromatic semi-crystalline polymer whose macromolecular main chain is composed of aryl groups, ketone bonds and ether bonds, and is a polymer family of “aromatic polyketones”. PEEK is located at the top of the polymer pyramid and has high comprehensive performance.

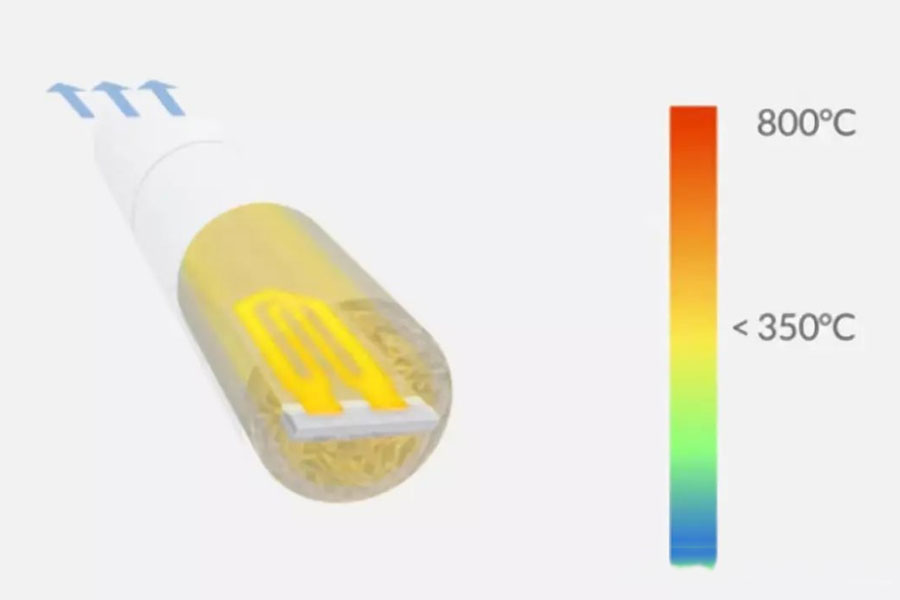

PEEK is currently used in the field of heat not burn electronic cigarettes in the shell of heat not burn electronic cigarettes, the base of the heating plate, the atomization chamber and other parts.

In addition to the PEEK material for the shell and heating base of IQOS, the QOQ of Yanfrog Technology and the CIGRIG of Cigrign are also made of PEEK material.

Why Use PEEK For HNB Accessories?

Mainly due to the excellent performance of PEEK:

- The aryl and ketone groups in the PEEK structure provide stiffness, which can ensure good mechanical properties and a high melting point, with a melting point of up to 343 °C;

- Compared with metal, PEEK-based materials are lightweight, easy to form, corrosion-resistant, and have higher specific strength (strength per unit weight);

- PEEK is UL94 V-0 compliant and resistant to burning up to 600°C with less smoke;

- PEEK has good biocompatibility, is non-toxic, and complies with FDA certification.

- During the heating process of heat-not-burn smoking devices, the surrounding temperature can reach as high as 300°C. The surrounding materials generally need to meet the characteristics of high temperature resistance and heat insulation, while the melting point of PEEK is as high as 343°C and the continuous use temperature is 260°C, which can adapt to heat-not-burn. High temperature characteristics of smoking articles.

In terms of Cnc machining material, PEEK, as a thermoplastic special engineering plastic, has both the heat resistance and chemical stability of thermosetting plastics and the molding processability of thermoplastics. It has good machinability and excellent dimensional stability. It can be used It can be processed in various ways such as turning, planing, milling, grinding, etc., and can accurately control tolerances.

PEEK has excellent melt fluidity and thermal stability after cnc machining temperature exceeds the melting point, and is easy to form. According to the product form: coarse powder, fine powder and granular material, there are also carbon fiber and glass fiber reinforced modified PEEK pellets. Granular materials are suitable for injection molding and extrusion molding; pure particle monofilament molding or cable coating for depth filtration; coarse powder or pure resin particles for composite modification of glass fiber, carbon fiber or other fillers; fine powder is suitable for molding Forming or spraying process.