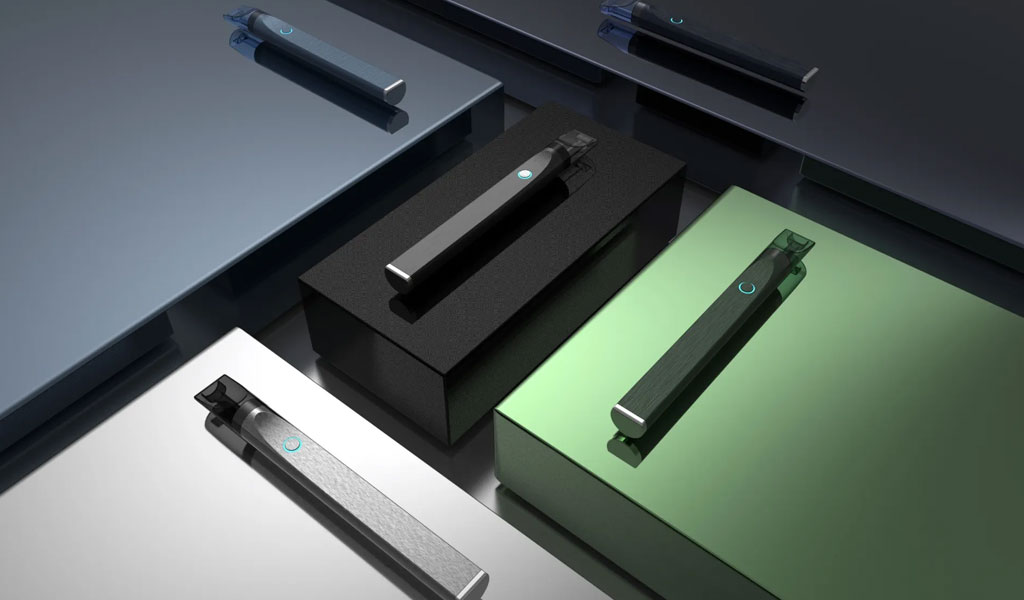

China is the place where electronic cigarettes were invented and the main production place, and 90% of the world’s electronic cigarettes are produced in Shenzhen, China. The author’s company is located in Dongguan, and there are currently several customers who are doing electronic cigarettes. Some of these projects have been followed up from the initial stage of the customer’s project. Yes, a customer just ordered the goods today, so I remembered to write an article about the plastic materials commonly used in electronic cigarettes, I just hope to provide some help to friends who need this.

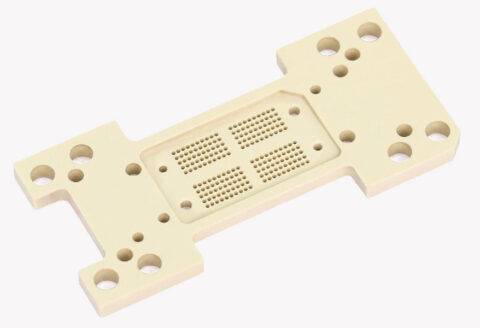

The electronic cigarette is mainly composed of three parts: the cigarette rod, the atomizer and the mouthpiece. The main components of the cigarette rod are batteries, circuits, etc. The atomizer is the core part of the electronic cigarette. The working principle of the electronic cigarette is to vaporize the liquid into steam by heating A china 3d printing process of atomization, and the device used for evaporating liquid into vapor is atomizer, which can generate high temperature of 200-300℃.

Around The Atomizer

The selection of plastic materials around the atomizer is very important, and generally it must meet the following requirements:

- It can reach the food grade and meet the environmental protection requirements (because this part needs to contain liquid smoke, it will eventually be inhaled into the body after atomization)

- There should be no odor under high temperature baking at full load power, and no irritating odor is required for low points (experienced old smokers will drive to the highest temperature without adding smoke liquid to smell the smell to determine the one used. Whether the material is qualified)

- It can withstand high temperature without deformation. Generally, it is required to continue to withstand high temperature for about 10 minutes, which is the time for one pipe of smoke (the high power of the atomizer produces a high temperature of 300 °C, and the low power produces a temperature of 210 °C).

- Good thermal conductivity, good heat insulation, can not turn off the electricity for several minutes, the electronic cigarette tube is still hot

So Which Plastics Can Meet These Requirements? Or Meet Some Of These Requirements?

- PEEK: the best performance, can meet all the above requirements, temperature resistance up to 340 ℃, no odor at high temperature, good thermal conductivity, food grade, medical grade material, but only a few companies in the world can produce this kind of plastic Raw materials, often used in aerospace and military fields, but machining PEEK materials are expensive, the price of raw materials is several hundred to several thousand yuan per kilogram, recycled materials (with Recycled materials) tens to hundreds of yuan per kilogram (recycled materials may have odor).

- PEI: It can meet most requirements, with a temperature resistance of about 200 ℃, amber translucent color, odorless at high temperature, good thermal conductivity, food grade, medical grade material, the world’s main manufacturer is the American SABIC Innovation , Mainly used in the field of engineering, the price of raw materials is about a few hundred dollars, and the recycled materials are tens to hundreds of dollars per kilogram.

- LCP: can meet most requirements, high temperature resistance of about 250 ℃, emits a fragrant odor similar to suet at high temperature, good thermal conductivity, halogen-free material, mainly used in high-temperature connectors and other electrical and electronic fields, there are many global Manufacturers can produce, and the price of raw materials ranges from dozens to more than one hundred.

- High temperature nylon: PA46, PA6T, PA9T, PPA, can meet some requirements, high temperature resistance 270 ℃, but the biggest disadvantage is that it will emit a faint fishy smell and slightly pungent at high temperature. This material is mainly used in engineering In the field, only DSM, Kuraray, Toray and other companies in the world can produce it.

- PPS: can meet some requirements, short-term temperature resistance of 260 ℃, good rigidity, can make metal sound when tapped, good smell at high temperature, good thermal conductivity, halogen-free medical grade series, there are 5 major manufacturers in the world, It is used instead of metal in a wide range of fields, and the price of raw materials ranges from dozens to more than one hundred.

Different grades of electronic cigarettes can take into account the requirements of odor, temperature, food grade and heat dissipation in terms of material selection. PEEK and PEI can be used for high-end products, LCP can be used for mid-range products, and high-temperature nylon and PPS materials can also be used for others. The material of the product is an important factor affecting the price of the product, which is also one of the main reasons why some of the same styles have huge price differences.

Cigarette Rod And Nozzle Part

The requirements for the plastic parts of the cigarette rod and the suction nozzle are not high, and generally need to meet: 1. Good appearance, can be sprayed, and can be electroplated; 2. The suction nozzle can meet the requirements of food grade and be environmentally friendly. 3. The material is hard and not easy to scratch.

The plastics in these positions can be selected such as PC, commonly known as bulletproof glue, which has excellent surface high gloss effect, high strength, can be sprayed and electroplated on the surface, resistant to high temperature of about 130 degrees, and the price is generally within ten to thirty yuan. , can reach food grade; other general-purpose plastics such as ABS, PP, PE and other general-purpose plastics can also be selected, these plastics are characterized by low price (the price is within 20 yuan), temperature resistance is only about 100 ℃, low strength, can Do electroplating and spray treatment; choose engineering plastics such as POM, PBT, etc. These plastics can withstand temperatures above 100°C.