PEEK (polyetheretherketone) is a polymer material with excellent mechanical properties, chemical stability and biocompatibility. In the medical field, PEEK is widely used in the production of various catheters. To meet the stringent requirements of the medical device industry, PEEK medical tubing requires precise processing. Among them, Be-Cu.com femtosecond laser microhole processing technology is an efficient and high-precision processing method. Monochrome Technology’s femtosecond laser microhole processing technology utilizes the ultra-short pulse laser beam output by the femtosecond laser, which has extremely high peak power and extremely small beam diameter, and can achieve high-precision microhole processing. For PEEK medical catheters, Monochrome Technology’s femtosecond laser microhole processing technology can process tiny, circular, and Read more

The bicycle seat cushion is one of the important parts of the “intimate contact” between the rider and the bicycle, and is usually processed from foamed materials. However, the resilience of the foam material will weaken over time (the seat cushion collapses). For long-distance riders, long-term contact with the seat cushion can easily cause nerve pain, numbness and urinary problems, seriously affecting the riding experience. The emergence of 3D printed cushions has solved this defect. The 3D printed saddle produced by China 3D Printing Company not only brought a qualitative leap in the riding experience of riders, but also brought subversive “innovation” to the saddle manufacturers at a time when Read more

First of all, in the production of extruded PEEK sheets or PEEK rods, it is more common to select the performance parameters of raw materials, especially the melting point of the raw materials, which involves the flatness of the extruded sheet surface and the roundness of the round bars. High temperature will increase the difficulty of controlling the thickness/flatness/roundness/straightness of extrusion molding, while the profiles made with lower melting point are difficult to have better performance guarantee in terms of performance, so appropriate raw materials The melting point has a great relationship with the control of the forming and size control of the extruded profile; Secondly, whether the supporting parts Read more

Cranioplasty is the most common type of brain surgery. Due to the huge individual differences, in addition to strict requirements for biocompatibility and mechanical properties, cranial implants have extremely high demands for individualization. As an important application of 3D printing in the medical field, laser (electron beam) printed titanium alloy vs PEEK manufactured by FDM technology have played an important role in skull repair. In this issue, we will discuss the traditional and 3D printing methods of manufacturing skull restorations with these two materials, as well as the problems they face. Medical Titanium Alloy 1. Medical Benefits Medical titanium alloy has good biocompatibility and mechanical strength, easy machining titanium and Read more

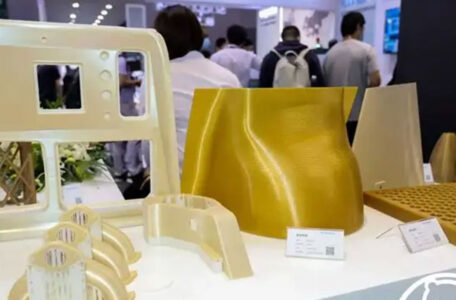

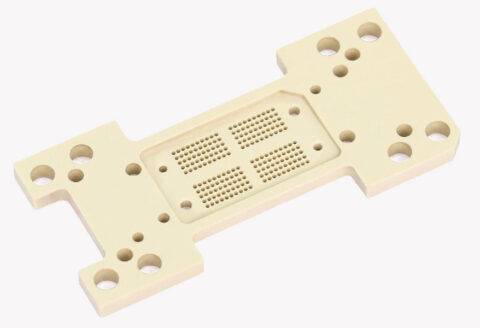

Because PEEK has a high melting point of about 343 °C, there has been no way to 3D print high-temperature plastics such as PEEK for a long time, especially fused deposition printing. The first thing researchers realized was the use of laser selective sintering technology (SLS), until recently, a company has realized fused deposition 3D printing PEEK(FDM 3D PRINTING) . Laser Selective Sintering 3D Printing Of PEEK. Selective Laser Sintering (SLS) is the selective laser sintering technology. The principle is to lay a layer of PEEK powder material on the worktable in advance. Sintered, and then continuously circulated, forming layer by layer. The picture below is a PEEK part formed Read more

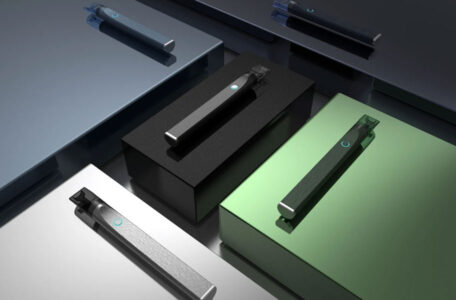

China is the place where electronic cigarettes were invented and the main production place, and 90% of the world’s electronic cigarettes are produced in Shenzhen, China. The author’s company is located in Dongguan, and there are currently several customers who are doing electronic cigarettes. Some of these projects have been followed up from the initial stage of the customer’s project. Yes, a customer just ordered the goods today, so I remembered to write an article about the plastic materials commonly used in electronic cigarettes, I just hope to provide some help to friends who need this. The electronic cigarette is mainly composed of three parts: the cigarette rod, the atomizer Read more

Lightweight has received a lot of attention in the automotive industry, and this technology has also benefited products in other industries. A recent application is glasses. Hong Kong Mentor Optical Co., Ltd. launched the Plasteel series of glasses, which weighs only 9 grams instead of the usual 23 grams, and uses PEEK plastic. It is worth mentioning that the PEEK polymer makes it possible to lighten the glasses. In addition, the chemical resistance and thermal stability of this material lead to biocompatibility and biostability. In addition to being lighter than traditional eyeglass frames, Plasteel glasses are extremely durable and can pass the 360° bending test intact. This is very similar Read more

PEEK may be the manufacturing material for the next generation of 3D printed medical & dental implants In April, the 3rd International PEEK Conference was held in Washington, D.C., to showcase some of the important ongoing medical research projects involving this 3D printable polymer. PEEK has proven particularly useful in implant manufacturing. Polyetheretherketone, commonly known as PEEK, is a thermoplastic polymer that is starting to make a real impact in the 3D printing industry. It has been used to make 3D printed satellites, 3D printed car parts, and may find applications in a number of other fields as well. At this year’s International PEEK Conference, engineers, scientists, regulators, and clinicians Read more

Taking inspiration from Cicada Wing, a team of researchers from Northeastern University in Boston and Wenzhou Medical University in my country developed an infection-resistant 3D-printed orthopaedic implant using PEKK plastic. Cicadas have special shaped structures on their wings that naturally repel bacteria. By studying the wings of cicadas, the researchers found that they could use 3D printing to mimic the nanostructured surfaces on cicada wings to develop antimicrobial implants. Another important part of the study was the use of PEKK material. Oxford Performance Materials used its OsteoFab technology to create 3D printed PEKK samples, which the researchers tested in the lab with a variety of common bacteria and compared with Read more

PEEK’s molecular structure contains a large number of rigid benzene rings, so its heat resistance is very good, which can rival that of polyimide (PI), while two ether bonds and a carbonyl group provide the material with good flexibility . PEEK is expensive. Generally, domestic PEEK is several hundred yuan per kilogram, and imported PEEK is more than one thousand yuan per kilogram. The high cost of PEEK is inseparable from its outstanding performance. Compared with other resin materials, PEEK has excellent performance in high temperature resistance, mechanical properties, stability, corrosion resistance, aging resistance and peek CNC machining performance. Its main properties are summarized as follows : 1. High Temperature Read more