The bicycle seat cushion is one of the important parts of the “intimate contact” between the rider and the bicycle, and is usually processed from foamed materials. However, the resilience of the foam material will weaken over time (the seat cushion collapses). For long-distance riders, long-term contact with the seat cushion can easily cause nerve pain, numbness and urinary problems, seriously affecting the riding experience. The emergence of 3D printed cushions has solved this defect.

The 3D printed saddle produced by China 3D Printing Company not only brought a qualitative leap in the riding experience of riders, but also brought subversive “innovation” to the saddle manufacturers at a time when the homogenization of bicycle saddles is serious.

How Does Custom 3D Printing Honeycomb Cushion

1.Design

Lattice design software LuxStudio

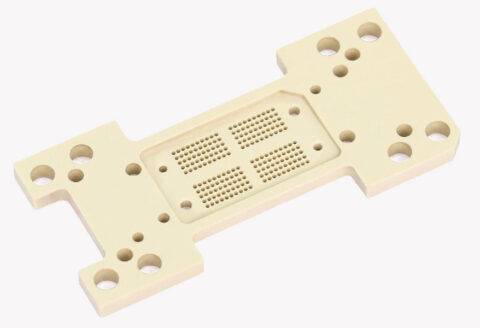

After the customer has determined the model of the 3D printed cushion, he can use LuxStudio, an additive manufacturing lattice design software independently developed by Be-Cu, to fill the lattice according to the mechanical requirements and choose the appropriate lattice appearance. (full automation)

LuxStudio has built-in a variety of lattices verified by Be-Cu’s mechanical simulation, which can not only realize the automatic generation of various structural lattices, but also generate ergonomic “gradient lattices” (gradient softness and hardness) according to the grayscale image; At the same time, taking into account the bonding process of the seat cushion and the metal base, LuxStudio is also specially equipped with the function of “adding a solid bottom surface” to facilitate the subsequent production of 3D printed seat cushions.

Print slice software LuxFlow

LuxFlow is a slicing software developed in depth according to industry applications. It provides functions such as “contour compensation” and support optimization for the elastic materials used in 3D printing cushions to ensure printing accuracy, improve printing success rate, and minimize material waste.

2.High elastic EM material

Different from foam, silica gel and other materials, Be-Cu’s 3D printing cushion is made of high-elastic photosensitive resin EM material, which has the characteristics of high resilience, strong shock absorption, tear resistance, and bending resistance, and its physical properties have reached the world’s leading level. And by the market verification and recognition of well-known brands.

After the parametric design of high-elastic EM materials and lattice software LuxStudio, the printed elastic products show more excellent rebound, shock absorption performance, and lighter weight. This is why Be-Cu 3D printed bicycle seat cushions have received many praises. one of the reasons.

Production

1.Printing device

In the different stages of the early development and testing of 3D printed bicycle honeycomb saddle products and the later production, Be-Cu can provide printing equipment with different formats, and meet the printing needs of different periods with the most cost-effective way.

2.Different size printers are available:

iLux Pro Engineering: 192×120×200mm, meeting the needs of early development and verification of material performance and lattice structure

Lux 3+: 293×165×380mm, suitable for small batch production

Lux 3Li+: 400×259×380mm, to meet the needs of larger batch production

3.Smart factory

For users of different production scales, they can choose to freely combine printers to complete the construction of small smart factories, or choose Be-Cu’s smart factory located in Ningbo to complete the printing needs.

Relying on the advantage of 3D printing that can be directly produced, when the cushion product is finalized and the parameters are determined, Be-Cu’s 3D printing equipment can maximize the printing yield (that is, the designed lattice size, performance, and precision), while meeting the flexible, Immediate delivery needs, there will be no worries about inventory backlogs.

The emergence of 3D printing has brought about a subversive manufacturing model, and has also broken the product limits of many industries, bringing breakthroughs in structure, performance, appearance, etc., so that products can stand out.

As the world’s leading MJF 3D printing smart manufacturer, Be-Cu Technology has brought many excellent products to the market with its leading design capabilities and 3D printing technology.