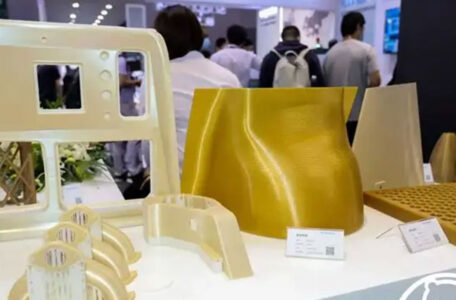

Because PEEK has a high melting point of about 343 °C, there has been no way to 3D print high-temperature plastics such as PEEK for a long time, especially fused deposition printing. The first thing researchers realized was the use of laser selective sintering technology (SLS), until recently, a company has realized fused deposition 3D printing PEEK(FDM 3D PRINTING) . Laser Selective Sintering 3D Printing Of PEEK. Selective Laser Sintering (SLS) is the selective laser sintering technology. The principle is to lay a layer of PEEK powder material on the worktable in advance. Sintered, and then continuously circulated, forming layer by layer. The picture below is a PEEK part formed Read more

Blog

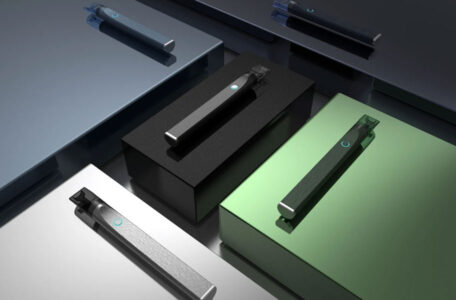

China is the place where electronic cigarettes were invented and the main production place, and 90% of the world’s electronic cigarettes are produced in Shenzhen, China. The author’s company is located in Dongguan, and there are currently several customers who are doing electronic cigarettes. Some of these projects have been followed up from the initial stage of the customer’s project. Yes, a customer just ordered the goods today, so I remembered to write an article about the plastic materials commonly used in electronic cigarettes, I just hope to provide some help to friends who need this. The electronic cigarette is mainly composed of three parts: the cigarette rod, the atomizer Read more

Lightweight has received a lot of attention in the automotive industry, and this technology has also benefited products in other industries. A recent application is glasses. Hong Kong Mentor Optical Co., Ltd. launched the Plasteel series of glasses, which weighs only 9 grams instead of the usual 23 grams, and uses PEEK plastic. It is worth mentioning that the PEEK polymer makes it possible to lighten the glasses. In addition, the chemical resistance and thermal stability of this material lead to biocompatibility and biostability. In addition to being lighter than traditional eyeglass frames, Plasteel glasses are extremely durable and can pass the 360° bending test intact. This is very similar Read more

PEEK may be the manufacturing material for the next generation of 3D printed medical & dental implants In April, the 3rd International PEEK Conference was held in Washington, D.C., to showcase some of the important ongoing medical research projects involving this 3D printable polymer. PEEK has proven particularly useful in implant manufacturing. Polyetheretherketone, commonly known as PEEK, is a thermoplastic polymer that is starting to make a real impact in the 3D printing industry. It has been used to make 3D printed satellites, 3D printed car parts, and may find applications in a number of other fields as well. At this year’s International PEEK Conference, engineers, scientists, regulators, and clinicians Read more

Taking inspiration from Cicada Wing, a team of researchers from Northeastern University in Boston and Wenzhou Medical University in my country developed an infection-resistant 3D-printed orthopaedic implant using PEKK plastic. Cicadas have special shaped structures on their wings that naturally repel bacteria. By studying the wings of cicadas, the researchers found that they could use 3D printing to mimic the nanostructured surfaces on cicada wings to develop antimicrobial implants. Another important part of the study was the use of PEKK material. Oxford Performance Materials used its OsteoFab technology to create 3D printed PEKK samples, which the researchers tested in the lab with a variety of common bacteria and compared with Read more

PEEK’s molecular structure contains a large number of rigid benzene rings, so its heat resistance is very good, which can rival that of polyimide (PI), while two ether bonds and a carbonyl group provide the material with good flexibility . PEEK is expensive. Generally, domestic PEEK is several hundred yuan per kilogram, and imported PEEK is more than one thousand yuan per kilogram. The high cost of PEEK is inseparable from its outstanding performance. Compared with other resin materials, PEEK has excellent performance in high temperature resistance, mechanical properties, stability, corrosion resistance, aging resistance and peek CNC machining performance. Its main properties are summarized as follows : 1. High Temperature Read more

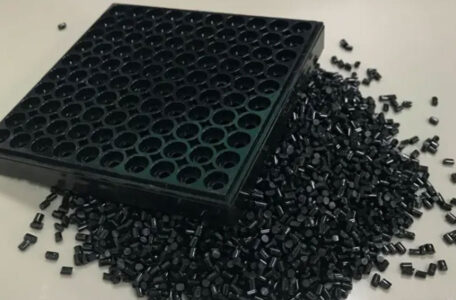

General-purpose plastics generally refer to polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), ABS, nylon (PA), etc. , Affect the wide range of plastic varieties. Engineering plastics refer to plastics with excellent comprehensive properties that can be used as industrial components to replace metal materials. The plastic has excellent mechanical properties, heat resistance, creep resistance, electrical insulation, etc., but the price is relatively expensive and the output is relatively small. Polycarbonate (PC), polyester (PET), polyoxymethylene (POM), nylon (PA), polyphenylene ether (PPO), and polyphenylene sulfide (PPS) are known as the world’s six largest engineering plastics. Special engineering plastics refer to engineering plastics with long-term use temperature above 150 ℃ and Read more

When it comes to polyetheretherketone, it is well known that if the plastic material is likened to a pyramid, PEEK is the one at the top of the tower. Polyetheretherketone resin (polyetheretherketone, PEEK resin for short) is a semi-crystalline, high-performance thermoplastic engineering plastic. PEEK has strong mechanical properties, chemical corrosion resistance, wear resistance, fatigue resistance and dimensional stability, high temperature resistance of 260 ° C, commonly used in construction machinery, aerospace products, etc. With other high temperature resistant plastics such as PI, PPS, PTFE, PPO and other high temperature resistant plastics, the upper limit of the operating temperature exceeds 50 °C. The Performance Of PEEK First of all, PEEK has Read more

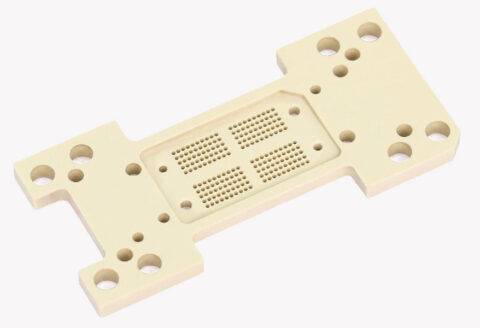

Washers are the parts that are placed between the connector and the nut. Compared with metal gaskets, plastic gaskets have excellent insulation, corrosion resistance, thermal insulation and non-magnetic properties, light weight, and are widely used in semiconductor, automotive, aerospace industry, interior decoration and other fields. Using more than 10 kinds of plastics, including PA66, PC, special engineering plastic PEEK with the best performance, modified PPS, PTFE, PP and PVD, etc. PA66【Nylon 66】 PA66 is a crystalline engineering plastic. It is a high toughness material with small friction coefficient, good wear resistance and excellent self-lubrication. Its oil resistance and chemical resistance are also very good, so it is most suitable for Read more

Polyetheretherketone (PEEK) special fiber is obtained by high temperature melt spinning of polyetheretherketone resin. Polyetheretherketone has high temperature resistance (UL temperature index 250℃), high strength (up to 94MPa for pure resin, 210MPa after fiber reinforcement), chemical resistance (except concentrated sulfuric acid, almost insoluble in any conventional chemical reagents), Irradiation resistance (109rad resistance, equivalent to nuclear reactor core radiation intensity), creep resistance (especially high temperature creep resistance, equivalent to nylon room temperature endurance at 150°C), high flame retardancy (0.3mm thick, can meet 94V -1; 1.5mm thick, can meet 94V-0), when fully burned, only H2O and CO2 are produced, no toxic gas is produced, and the high temperature hydrolysis resistance is excellent Read more