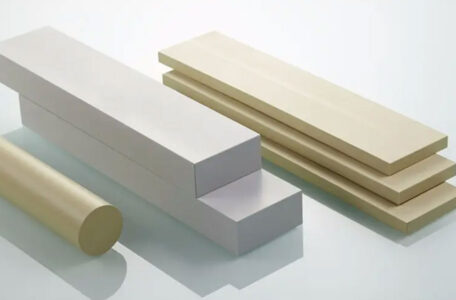

Peek polyether ether ketone is a special engineering plastic with excellent properties such as high temperature resistance, self-lubrication, easy processing and high mechanical strength, which can be manufactured and processed into various mechanical parts, such as automobile gears, oil screens, shift start disks ; Aircraft engine parts, automatic washing machine runners, medical equipment parts, etc.PEEK main features: Corrosion resistance, anti-aging Solubility resistance; High temperature, high frequency, high voltage electrical performance conditions Both toughness and rigidity; Dimensional requirements Precise conditions Radiation wear resistance, corrosion resistance Condition Water resistance Solution, excellent characteristics can still be maintained under high temperature and high pressure; Lightweight replacement of metal for optical fiber components Good wear Read more

Blog

Polyetheretherketone (PEEK) is a high polymer composed of repeating units containing one ketone bond and two ether bonds in the main chain structure, and is a special polymer material. It has physical and chemical properties such as high temperature resistance and chemical resistance. It is a kind of semi-crystalline polymer material. It can be used as high temperature resistant structural material and electrical insulating material. It can be compounded with glass fiber or carbon fiber to prepare reinforcing material. Generally, a type of polyarylene ether polymer obtained by condensation with aromatic dihydric phenol is used. This material has numerous applications in aerospace, medical devices (as artificial bone to repair bone Read more

The widespread use of polymers has transformed our lives over the past 75 years or so. From commodity plastics to high performance polymers (HPP). Like PEEK, both can function in very demanding applications. PEEK not only plays an important role in the plastic part of the antenna port of the iPhone, but also has been widely used in the new HNB smoking set, and is the core raw material for heating peripheral components. Many of China’s top heat-not-burn products are using PEEK’s material solutions. What Is PEEK Material? Polyetheretherketone (English name polyetheretherketone, PEEK for short) refers to a linear aromatic semi-crystalline polymer whose macromolecular main chain is composed of aryl Read more

In a market like the aerospace industry, where building just one new aircraft costs millions of dollars and man-hours, a company will only start to see a return on investment after five to ten years, if it pays off. With such a time span and cost so high, aerospace companies are always looking for ways to make their planes lighter, more fuel-efficient and cost-effective for potential buyers. One way airlines such as Boeing and Airbus are achieving these goals is by turning to specialty materials such as PEEK to reduce weight while still retaining the properties of metals. Developed in the 1980s, PEEK (polyetheretherketone) is a thermoplastic belonging to the Read more