PEEK (polyetheretherketone) is a polymer material with excellent mechanical properties, chemical stability and biocompatibility. In the medical field, PEEK is widely used in the production of various catheters. To meet the stringent requirements of the medical device industry, PEEK medical tubing requires precise processing. Among them, Be-Cu.com femtosecond laser microhole processing technology is an efficient and high-precision processing method.

Monochrome Technology’s femtosecond laser microhole processing technology utilizes the ultra-short pulse laser beam output by the femtosecond laser, which has extremely high peak power and extremely small beam diameter, and can achieve high-precision microhole processing. For PEEK medical catheters, Monochrome Technology’s femtosecond laser microhole processing technology can process tiny, circular, and irregular-shaped holes on its surface. The diameter and depth of the holes can be precisely controlled as needed.

- High-precision micro-hole processing: Femtosecond laser has extremely high beam quality and small focus point, which can achieve very fine micro-hole processing. This is important for medical catheters because the size and shape of the micropores have a significant impact on the performance and functionality of the catheter. Femtosecond laser processing enables microvia production with high precision, consistency and repeatability.

- No heat-affected area: Traditional processing methods, such as mechanical cutting or thermal cutting, may produce heat effects in the cutting area, resulting in thermal damage, deformation or melting of the material. Femtosecond laser processing has extremely short pulse action time and almost no heat conduction, so it can achieve micro-hole processing in heat-free areas and protect the material properties and structural integrity of laser cut PEEK conduits to the greatest extent.

- Smooth hole walls and burr-free: Femtosecond laser processing can achieve smooth hole walls, reducing friction and damage to the inner wall of the catheter. Compared with traditional machining methods, femtosecond laser microhole processing does not produce burrs, chips or ablation, ensuring a smooth surface inside the catheter.

- Material retention properties: PEEK material has excellent chemical stability and biocompatibility, making it suitable for medical applications. Femtosecond laser processing has less impact on the material and can maintain the material properties and characteristics of the PEEK catheter without introducing additional chemical or physical properties.

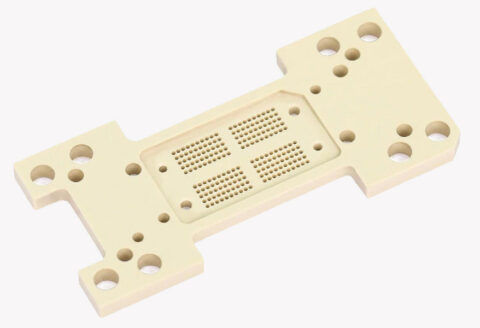

- Flexibility and diversity: Femtosecond laser processing can achieve micropore structures of various shapes and sizes to meet different catheter design requirements. Whether it is a single microhole or a complex array of microholes, femtosecond lasers can be flexibly implemented.

It should be noted that femtosecond laser microhole processing for PEEK medical catheters requires parameter optimization and processing control based on specific applications and design requirements. In addition, appropriate safety measures need to be taken during processing to ensure the safety of operators and the environment.