Because PEEK has a high melting point of about 343 °C, there has been no way to 3D print high-temperature plastics such as PEEK for a long time, especially fused deposition printing. The first thing researchers realized was the use of laser selective sintering technology (SLS), until recently, a company has realized fused deposition 3D printing PEEK(FDM 3D PRINTING) .

Laser Selective Sintering 3D Printing Of PEEK.

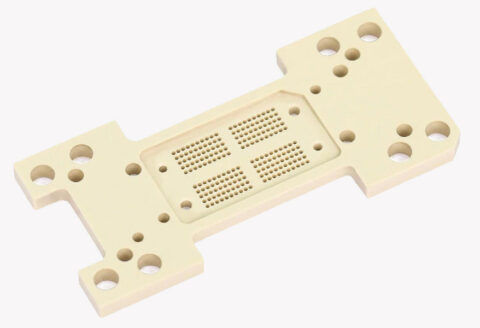

Selective Laser Sintering (SLS) is the selective laser sintering technology. The principle is to lay a layer of PEEK powder material on the worktable in advance. Sintered, and then continuously circulated, forming layer by layer. The picture below is a PEEK part formed by be-cu.com’s SLS printer. The raw material used is PEEK HP3 and the flame retardant grade is FAR 25.853/UL 94 V0. At present, SLS 3d printing technology is widely used in 3D printing PEEK Parts technology.

Fused Deposition Printing Technology Of PEEK

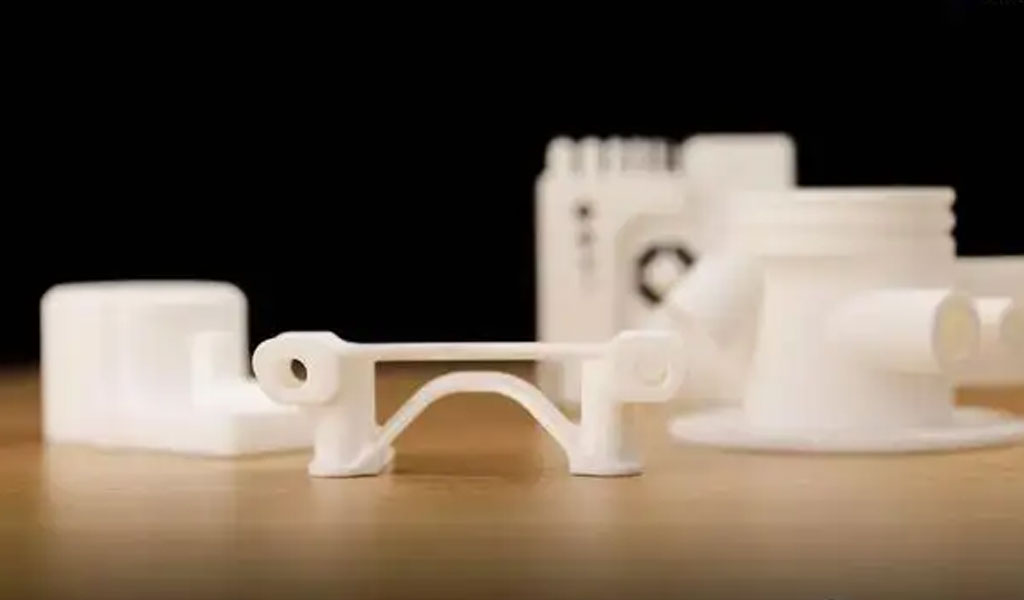

Fused Deposition Modeling (FDM), or Fused Deposition Modeling, is the second most widely used technology in 3D printing. The material of FDM is generally thermoplastic material, such as wax, ABS, nylon, etc. Supplied in filament form. The material is heated and melted in the nozzle. Under the control of a pre-designed computer program, the nozzle moves along the section profile and filling trajectory of the part, and at the same time extrudes the molten material. The material rapidly solidifies and forms with surrounding materials.

Because PEEK has a high melting point of about 343 °C, FDM printing of PEEK has not been possible for a long time. However, recently, INDMATEC has realized FDM printing technology for materials such as PEEK, PTFE and PPSU. They have launched a product called Printing High Temperature Polymerization The FDM type 3D printer of PEEK, called PEEK 3D printer, has a maximum 3D printing size of 155 x 155 x 155 mm and is equipped with a hot end that can support high temperatures of 420 degrees Celsius. This allows it to print 3D objects using PEEK filament. The 3D printer PEEK parts service has a market retail price of 9590 euros and has the ability to print high temperature and high performance polymers.

PEEK is used to replace titanium and stainless steel in medical orthopedics with its excellent performance. However, due to the high cost of traditional open-molding injection molding and the inability to realize complex geometric parts, it is difficult to achieve personalized customization of patients. However, 3D printing technology The lower cost solves this problem, so the 3D printing of PEEK will play an increasingly important role in the field of orthopedic medical treatment, and the prospect is bright.

Because the melting point of PEEK is too high (more than 300 degrees Celsius), in the field of 3D printing, fused deposition modeling (FDM) is generally not used, and most 3D printing of PEEk is limited to selective laser sintering (SLS).

However, a foreign company, INDMATEC, has acquired the technology to prepare PEEK filaments for fused deposition printing. INDMATEC said that through the use of an all-metal hot-end extruder, temperatures as high as 400 degrees Celsius can be obtained, so that their PEEK filaments can also be used. used. Although INDMATEC claims that PEEK is more expensive than aluminum and other technical polymers, it is still very cost-effective in terms of performance and price. A 200-gram roll of 1.75mm wire retails for just over $150. But not just any FDM 3D printer can print with it. INDMATEC will provide consulting assistance for users to print with PEEK filament through existing FDM 3D printers.

Recently, INDMATEC company went a step further and specially launched an FDM type 3D printer capable of printing high-temperature polymer PEEK, called PEEK 3D printer. end. This allows it to print 3D objects using PEEK filament. The PEEK 3D printer has a market retail price of 9590 euros and has the ability to print high temperature and high performance polymers.