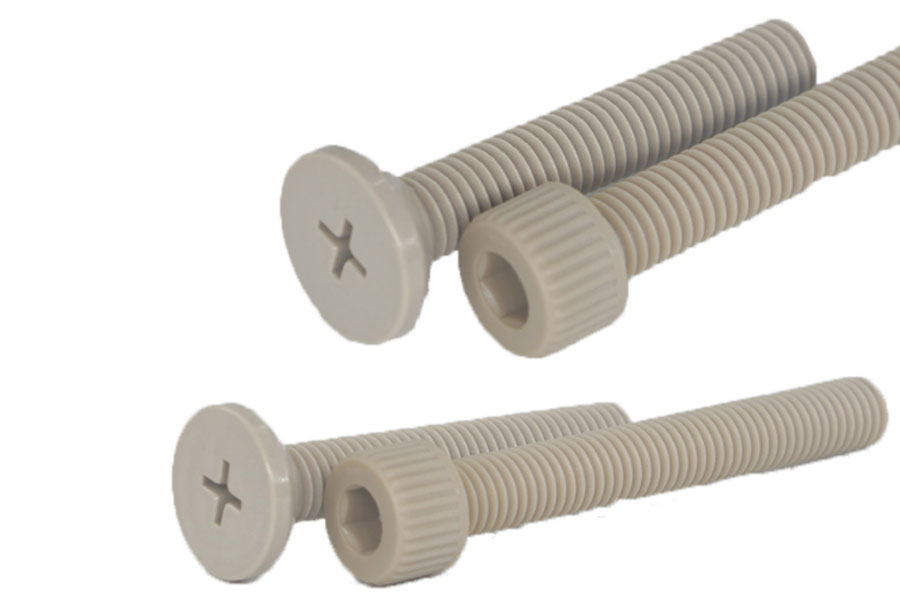

High Temperature Flame Retardant Peek Screw

Custom High Temperature Flame Retardant Peek Screw machining service include milling, boring, drilling, tapping, EDM, routing, rolling, routing, laser cutting, waterjet cutting, facing, threading, reaming, taper turning, tapping, knurling, gear hobbing, broaching, cutting, counterboring, countersinking. Secondary operations include assembly, centerless grinding, heat treating, polishing, electroplating, powder coating and welding. Materials include metals (including aluminum, carbon steel, stainless steel, brass, aluminum, beryllium, copper, tungsten, molybdenum, nickel, titanium, zinc), plastics and composites (including acetal, acrylic, ABS, PC, PTFE, PE, PVC, POM, PMMA, PVDF, DHPE, HDPE, PPS and PEEK) and wood.

Capable of handling parts from 0.08 to 80 inches (2-500mm) length by 0.08 to 30 inches (2-500mm) wide and 0.08 to 20 inches (2-2000mm) inches diameter. Parts turning from 0.1 to 36 inches in length and 0.1 to 24 inches diameter. Tolerance ranges up to +/-0.0005 inches.

Serving many different industries with offshore contract manufacturing, automation, OEM/ODM, engineering, product development, prototyping, pilot production, quality assurance and supply chain management services. Meets ASTM, ANSI, D2000, REACH, NSF, ISO, RoHS, WEEE and IPC 1752-1, AS9100D, UL, TUV, NSF and others, as required.

Categories: Automobile Manufacturing, Instrument And Meter, PEEK CNC Turning Parts, PEEK Swiss Machining Parts, Precision Devices