Taking inspiration from Cicada Wing, a team of researchers from Northeastern University in Boston and Wenzhou Medical University in my country developed an infection-resistant 3D-printed orthopaedic implant using PEKK plastic. Cicadas have special shaped structures on their wings that naturally repel bacteria. By studying the wings of cicadas, the researchers found that they could use 3D printing to mimic the nanostructured surfaces on cicada wings to develop antimicrobial implants.

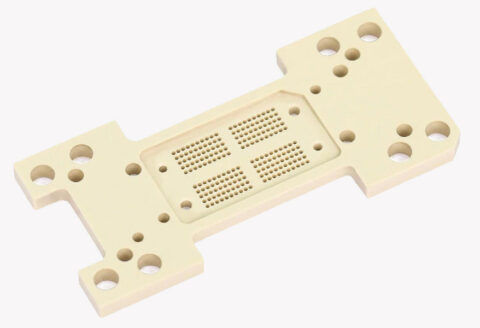

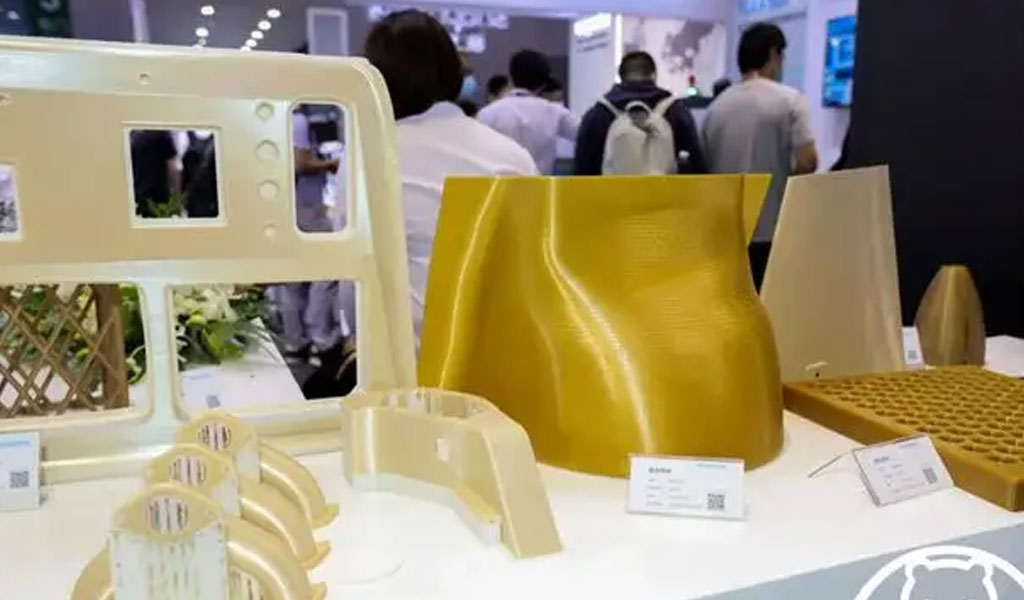

Another important part of the study was the use of PEKK material. Oxford Performance Materials used its OsteoFab technology to create 3D printed PEKK samples, which the researchers tested in the lab with a variety of common bacteria and compared with samples made with PEEK, a standard orthopaedic industrial material. comparisons were made.

After a few days, the PEKK samples showed amazing results. For example, after five days in the lab, PEKK samples had 37 percent less S. epidermidis than their PEEK counterparts. In addition, the researchers found that the number of Pseudomonas aeruginosa, another bacterium that causes implant infections, decreased by 28 percent on PEKK samples after one day of incubation and 50 percent after five days. Surprisingly, all of these bacterial reductions were achieved without the use of any antibiotics. “This study is the first to demonstrate that a variety of antimicrobial orthopaedic implants can be fabricated from nanostructured PEKK,” says the study’s abstract.

The findings suggest that the use of China 3D printed nanostructures and PEKK materials has the potential to reduce bacterial infections caused by orthopedic implants. The study has been published in the International Journal of Medicine, titled “Antibacterial Properties of PEKK for Orthopedic Applications.”