Peek polyether ether ketone is a special engineering plastic with excellent properties such as high temperature resistance, self-lubrication, easy processing and high mechanical strength, which can be manufactured and processed into various mechanical parts, such as automobile gears, oil screens, shift start disks ; Aircraft engine parts, automatic washing machine runners, medical equipment parts, etc.PEEK main features:

- Corrosion resistance, anti-aging

- Solubility resistance;

- High temperature, high frequency, high voltage electrical performance conditions

- Both toughness and rigidity;

- Dimensional requirements Precise conditions

- Radiation wear resistance, corrosion resistance Condition

- Water resistance Solution, excellent characteristics can still be maintained under high temperature and high pressure;

- Lightweight replacement of metal for optical fiber components

- Good wear resistance, anti-static electrical insulation performance;

- High mechanical strength requirements

- Low smoke and gas emissions.

The Main Application Of Peek Special Materials

The main application fields of PEEK are: the transportation industry market such as automobiles (including aviation) accounts for about 50% of the consumption of PEEK resin, semiconductor manufacturing equipment accounts for 20%, general mechanical parts such as compressor valves account for 20%, medical equipment and Other markets such as analytical instruments account for 10%.

1. Transportation machinery such as automobiles

The growth of PEEK resin in the European market, especially in the auto parts market, is the fastest, especially in the parts around the engine, transmission parts, steering parts, etc., which use PEEK plastics instead of some traditional high-priced metals as manufacturing materials. Demand for PEEK resins will continue to grow as the automotive industry adapts to miniaturization, lightweighting and cost reduction. A European model has 44 parts that use PEEK plastic instead of traditional metal products.

2. The field of IT manufacturing

Semiconductor manufacturing and the electrical and electronic industry are expected to be another growth point for PEEK resin applications. In the semiconductor industry, in order to achieve high functionality and low cost, the size of the silicon wafer is required to be larger and the manufacturing technology is more advanced. special requirements, this will be where PEEK resins come into play.

3. The field of office machinery parts

For the separation claws, special heat-resistant bearings, chains, gears, etc. of copiers, when PEEK resin is used instead of metal as their material, the parts can be lightweight, fatigue-resistant, and can be lubricated without oil.

4. The field of wire coating

PEEK coating has good flame retardancy, and its flame retardant level can reach UL94 V-0 level without any flame retardant. PEEK resin also has the advantages of peel resistance and radiation resistance (109 rad), so it is used in special wires in military and nuclear energy and other related fields.

5. Plates, bars and other fields

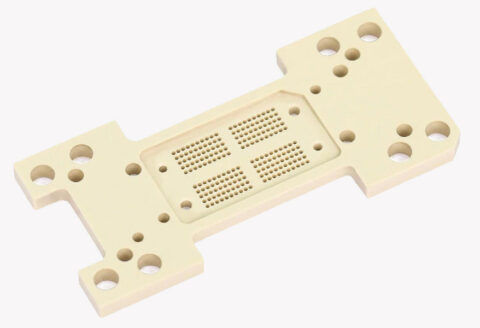

In the application process of PEEK in some special fields, the phenomenon of small quantity and large variety is often encountered. At this time, it is very advantageous to use rods, plates and other profiles for machining and manufacturing.

6. Fiber field

PEEK fiber (including monofilament) industrial filter cloth, industrial brushes and other products. In the field of composite materials, the appeal of PEEK fiber lies in its thermoplasticity and high temperature resistance. In addition to heat resistance in industrial filter cloths and industrial brushes, its appeal lies in its chemical resistance and abrasion resistance.

7. The field of medical analysis equipment

Because PEEK can withstand repeated autoclaving, it can be used in medical equipment to manufacture endoscope parts, dental descaling devices, etc. In addition, due to the high strength and low dissolution of PEEK, it has been used in liquid chromatography columns, tubes, accessories, etc. for instrumental analysis. Moreover, because PEEK has good compatibility with the human body, it has successfully replaced the traditional titanium metal as an artificial bone material. The main application areas of PEEK.

The Grade Of Peek Special Materials

- 150CA30 :30% carbon fiber reinforced, good high temperature resistance, good rigidity and strength, suitable for mechanical, electrical, automotive, chemical and other engineering products with good chemical resistance

- 150CA40 :Injection, extrusion grade, 40% carbon fiber reinforced, high rigidity, high temperature resistance, for engineering parts

- 150P :Coating grade, low viscosity, powder, unreinforced, crystalline type, UL94V-0, use temperature above 160℃, suitable for metal coating

- 380G:Extrusion and coating grades. Medium viscosity, mixture pellets, unreinforced, crystalline type, UL94V-0, use temperature above 160℃. Suitable for monofilament and general general purpose extrusion engineering parts, especially metal wire coating

- 380P:Extrusion and coating grades. Medium viscosity, powder, unreinforced, crystalline type, UL94V-0, use temperature above 160℃, suitable for monofilament and general general extrusion engineering parts, such as metal wire coating

- 450CA30:Injection molding reinforced grade. Mixed pellets, 30% carbon fiber reinforced, have good rigidity and load-bearing properties, the operating temperature is above 250 ° C, the maximum temperature can reach 315 ° C, UL94V-0, good toughness, high strength, good chemical corrosion resistance, and fast molding cycle.

- 150FC30:Injection, extrusion grade, 30% carbon fiber reinforced, high rigidity, high temperature resistance, good lubricity, used as engineering parts

- 450G:Injection molding grade, non-reinforced, high viscosity, mixture pellets, crystalline type, UL94V-0, use temperature above 160℃, high strength

- 450P:Injection grade, powder, features and uses are the same as 450G

- 450GL20:Enhanced injection molding grade. Mixture pellets, 20% glass fiber reinforced, higher heat resistance and flexural modulus than 450G grades, high strength and stiffness, use

- 450GL30:The temperature is 250℃, which is UL94V-0. Suitable for mechanical, chemical, electrical and other engineering products, also used for extrusion products.

- D150CA30:New product, enhanced injection molding grade. Glass fiber and carbon fiber reinforced, mixed pellets, good fluidity, good heat resistance, continuous use temperature of 250 ° C, up to 300 ° C above. Suitable for high-quality thin-walled engineering products such as machinery and electrical

- D150G:New product, injection molding grade. Mixed pellets, good fluidity, good heat resistance, use temperature 250 ℃, stable mechanical properties.

- D150GL30:New product, injection molding reinforced grade. 30% glass fiber reinforced, mixed pellets.

- D450HT15:New products, various engineering products with good performance, suitable for heavy-duty applications, can replace more traditional metals

- D450HF30:450GL10:

New product, reinforced injection molding grade, 10% glass fiber, good strength and rigidity, high heat resistance, as mixture pellets - KX3:New product, injection molding grade. Mixture pellets. Suitable for engineering products such as bearings

- LC1006:Injection reinforced grade, 30% carbon fiber reinforced, high temperature resistance, good rigidity and strength, suitable for mechanical, electrical, chemical, automotive and other good lubricity

- LF1006:Injection molding reinforced grade, 30% chopped fiber, the same characteristics and uses as LC1006

- LFL4036:Injection reinforced grade, 45% chopped fiber and PTFE, high temperature resistance, good rigidity and strength, suitable for mechanical, electrical, automotive, chemical and other productsLL4530:Injection molding reinforced grade, 20% silicone resin modification, high temperature resistance, good rigidity and strength, suitable for lubricating products such as machinery, electrical, automobile, chemical industry, etc.

- PDX79737:Injection reinforced grade, 30% chopped glass fiber reinforced, high temperature resistance, good rigidity and strength. Suitable for mechanical, electrical, automotive, chemical products

- PDX79738:Injection reinforced grade, 30% carbon fiber, features and uses are the same as PDX79737

- PDX81319:Injection reinforced grade, 15% carbon fiber, features and uses are the same as PDX79737

- PDX81336:Injection reinforced grade, 45% carbon fiber and PTFE filled and reinforced, others are the same as PDX79737

- PDX81338:Injection molding reinforced grade, filled with 20% PTFE, high temperature resistance, good rigidity and strength, suitable for engineering products of mechanical, electrical, chemical, automotive and other chemical coupling

- PDX87229:

- > 20% short glass fiber filling, high temperature resistance, good rigidity and strength, suitable for engineering products with hydrolysis stability such as machinery, electrical, chemical, automobile, etc.

- PDX87461:>15% short glass fiber filling, high temperature resistance, good rigidity and strength, suitable for mechanical, electrical, chemical, automotive and other tensile-resistant engineering products

- WA40:Injection molding reinforced grade, 40% aluminum scrap filling, high temperature resistance, good rigidity and strength, suitable for mechanical, electrical, automotive, chemical and other products with good lubricity

- WC-1006:Injection reinforced grade, 30% carbon fiber reinforced, high temperature resistance, good rigidity and strength, suitable for antistatic products such as machinery, electrical, automobile, chemical industry, etc.

Polyetheretherketone (PEEK) resin is a special engineering plastic with excellent performance. Compared with other special engineering plastics, it has many significant advantages, such as high temperature resistance, excellent mechanical properties, good self-lubrication, chemical corrosion resistance, flame retardant, Peeling resistance, radiation resistance, stable insulation, hydrolysis resistance and easy processing, etc., have been used in aerospace, automobile manufacturing, electrical and electronic, medical and food processing and other fields.

Excellent performance and wide application PEEK resin was first used in the aerospace field, replacing aluminum and other metal materials to manufacture various aircraft parts [4] In the automotive industry, because PEEK resin has good friction resistance and mechanical properties, it is used in the manufacture of engine inner covers. Various components such as bearings, gaskets, seals, clutch gear rings, etc. made of it are widely used in automobile transmission, braking and air conditioning systems. PEEK resin is an ideal electrical insulator. It can still maintain good electrical insulation performance under harsh working conditions such as high temperature, high pressure and high humidity. Therefore, the field of electronic information has gradually become the second largest application field of PEEK resin, manufacturing and transporting ultrapure water. In the semiconductor industry, it is often used to manufacture wafer carriers, electronic insulating diaphragms and various connecting devices. As a semi-crystalline engineering plastic, PEEK is insoluble in almost all solvents except concentrated sulfuric acid, so it is often used to make compressor valve plates, piston rings, seals and various chemical pump bodies and valve parts. PEEK resins can also withstand up to 3000 cycles of autoclaving at 134°C, a feature that makes them useful in the production of sterilization-critical, reusable surgical and dental equipment. The molding temperature of PEEK is 320 degrees ~ 390 degrees, the baking temperature is 160~1855H~8H, and the mold temperature is 140~180. The molding temperature of this material is too high, and the damage to the screw is serious. When setting the screw speed, the speed should not be too fast, and the injection pressure should be 100 ~130MPa injection speed 40~80. After molding, the screw should be quickly cleaned with PE wax, and the PEEK material should not be allowed to stay in the screw.