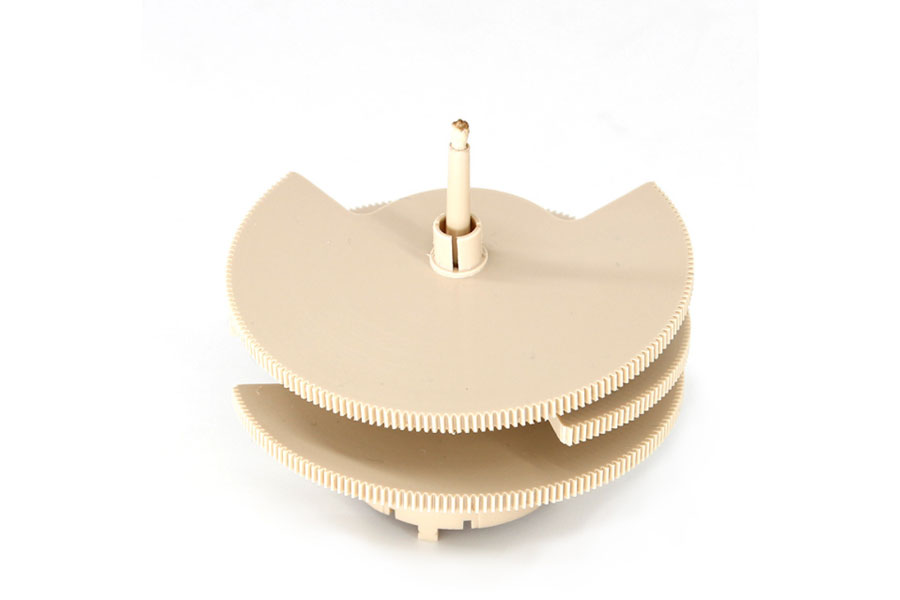

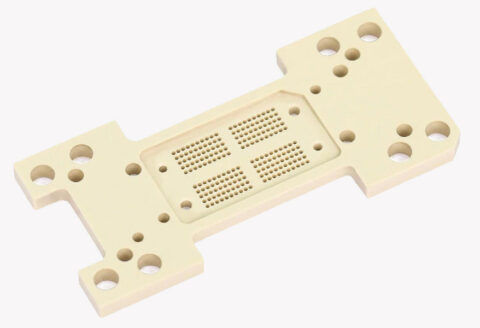

Precision Injection Molding PEEK Gear

Precision Injection Molding of PEEK Gear components and parts for the aerospace, agriculture, automotive, recreational, electronics, industrial, oil and gas and green energy markets. Manufacturing capabilities include CNC turning, milling, Swiss CNC and automatic screw machining, rotary transfer machining and multiple spindle machining.

Secondary operations include broaching, deburring, drilling, finishing, grinding, knurling, sawing, specialty parts cleaning, stamping, tapping and thread rolling. Long and short runs, prototype to production.

Contract manufacturing and machining services are supported by LEAN, ERP, EDI, Kanban, Consignment and GSCM.

Advanced manufacturing and business practices such as Professional Program Management, new product co-development, DFM assessments, single point of contact global and domestic supply chain management are available for applicable projects.

Provide drawings (format: CAD, PDF, JPG, step, etc.) or samples. Information includes: quantity, material, precision tolerance, surface treatment and special requirements.Our company can modify or design the drawings appropriately according to customer needs. You can directly send the drawings to info@pintejin.com and notify by phone or information.

Categories: Medical Care And Health Care, PEEK Injection Molding Parts, Precision Devices